3D Printing Services / Print Farm

Full-color, multi-material, multi-head 3D printing with flexibility and speed

Full-color, multi-material, multi-head 3D printing with flexibility and speed

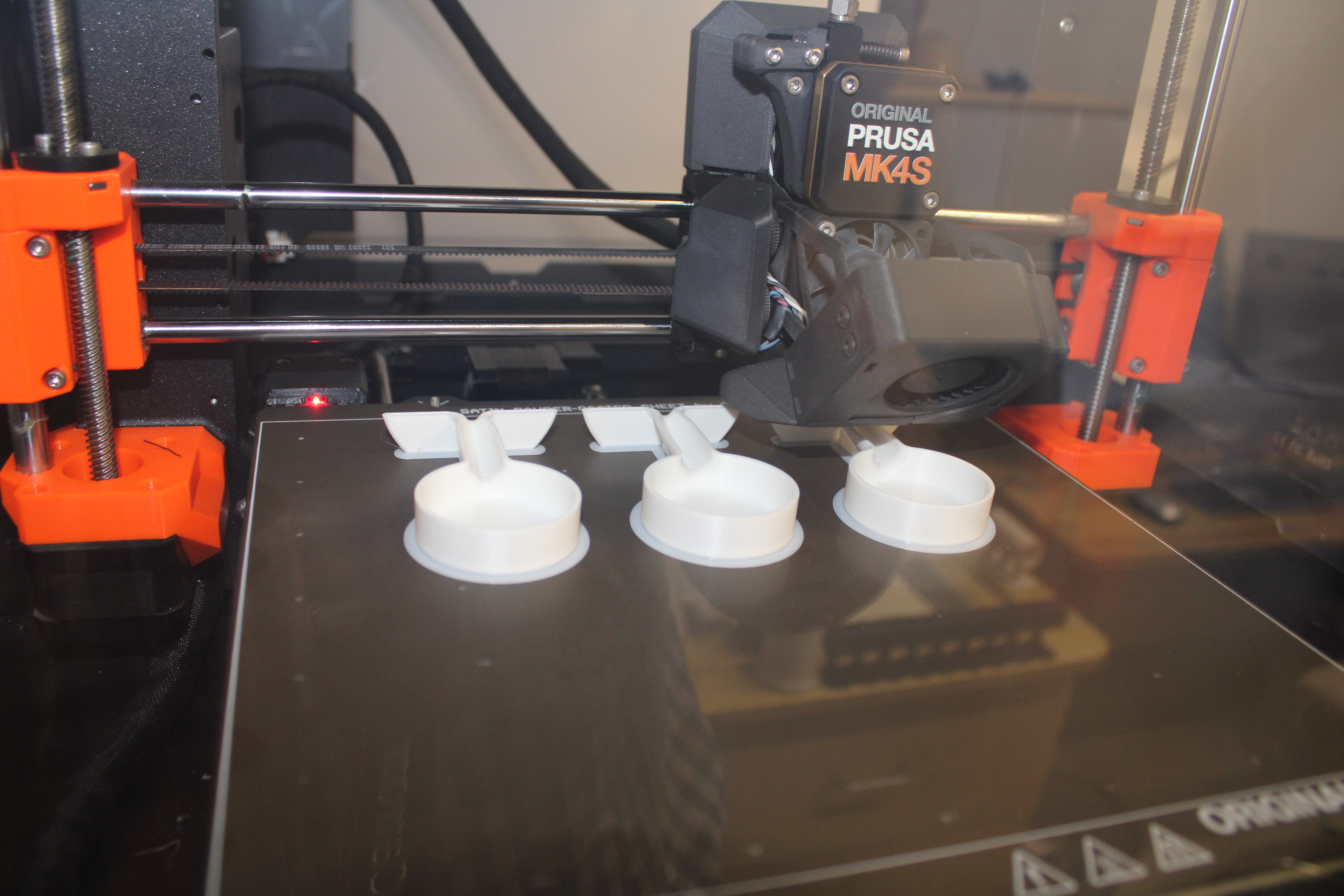

At 865FabLab, our 3D printing farm is engineered to deliver high-throughput, multi-material parts using a combination of tool‑changing and single‑extruder systems. We can support complex parts, color differentiation, and multiple material combinations in a single print job — or scale with parallel production runs across machines.

Our Setup & Capabilities

-

Multi-head tool changer unit supports up to five independent extruders for multi-color or multi-material prints in a single build

-

CoreXY mechanics for faster, smooth motion

-

Large build volumes for bigger parts or assemblies

-

Multiple single-extruder units in parallel for high output of simpler parts

-

Support for standard filament materials like PLA, PETG, ABS, TPU, and specialty blends

-

Automatic calibration & leveling ensures reliable first layers and consistent output

-

Networked print farm workflow for remote monitoring, job scheduling, and batch management

Workflow & Process

-

Submit your 3D model file (STL, STEP, OBJ, etc.)

-

Discuss material requirements and multi-material strategies

-

We optimize the job across print heads or machines

-

Print & monitor through our farm management system

-

Post-processing — support removal, sanding, assembly, etc.

-

Ship or pick up, packaged and ready to integrate

Typical Print Specifications

Parameter Typical Performance Build volume (multi-head) ~360 × 360 × 360 mm (or equivalent “large-cube” envelope) (Prusa3D by Josef Prusa) Extruder count Up to 5 heads for simultaneous material/color printing (Prusa3D by Josef Prusa) Print resolution ~0.1 mm (100 µm) to ~0.3 mm (300 µm) depending on model and use case Filament diameter 1.75 mm Material types PLA, PETG, ABS, TPU, engineering blends, composites.

Ideal Use Cases

-

Functional prototype parts needing multi-material structure

-

Enclosures, housings, brackets, and interfaces

-

Custom jigs, tooling, fixturing, and aligners

-

Model parts with embedded multi-color detail or gradients

-

Low-run parts or custom one-offs where cost, speed, and complexity matter

-

Batches of simpler parts produced in parallel on single-extruder units

Materials & Material Strategies

We can print with a variety of filament materials, and combine them intelligently in a single print:

-

Rigid plastics: PLA, PETG, ABS, ASA

-

Flexible / elastomeric: TPU, TPE

-

Composite & specialty blends: carbon-fiber, glass-filled, etc.

-

Support materials / internal scaffolding: dissolvable or breakaway supports

-

Multi-color and multi-material builds using tool-changer head(s)

With our multi-head system, we can assign different materials or colors to individual sections of your model, or craft infill/support strategies that use alternate materials for ease of removal.

In-store branding and signage

Window displays and visual merchandising

Themed event signage or sculptural props

Photo booth backdrops or 3D logos

High-end dimensional branding for walls and fixtures

Displays for malls, airports, and showrooms

Get Started with 3D Printing

Whether you need a complex multi-material prototype or a high-volume run of functional parts, our print farm delivers flexibility and speed.

Start a 3D Printing Project

3D Printing FAQ's

-

Can you mix different materials in the same print?

Yes — using our multi-head tool-changing printer, we can combine rigid, flexible, or composite materials within a single build.

-

What is the maximum size you can print in one piece?

We can print parts up to the envelope of our largest multi-head machine (typically ~360 × 360 × 360 mm). Larger parts can be split and assembled.

-

Do you run prints in parallel?

Yes — simpler parts may run concurrently on our fleet of single-extruder units. This helps reduce queue times and increases throughput.

-

What file types do you accept?

We accept STL, OBJ, STEP/IGES, 3MF, and other standard 3D formats. We also assist with file cleanup and slicing optimization.

-

Is finishing or assembly included?

Yes — we offer support removal, sanding, priming, minor assembly, and batching services as needed.

-

Do you offer shipping or pickup?

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.

-1.jpg)

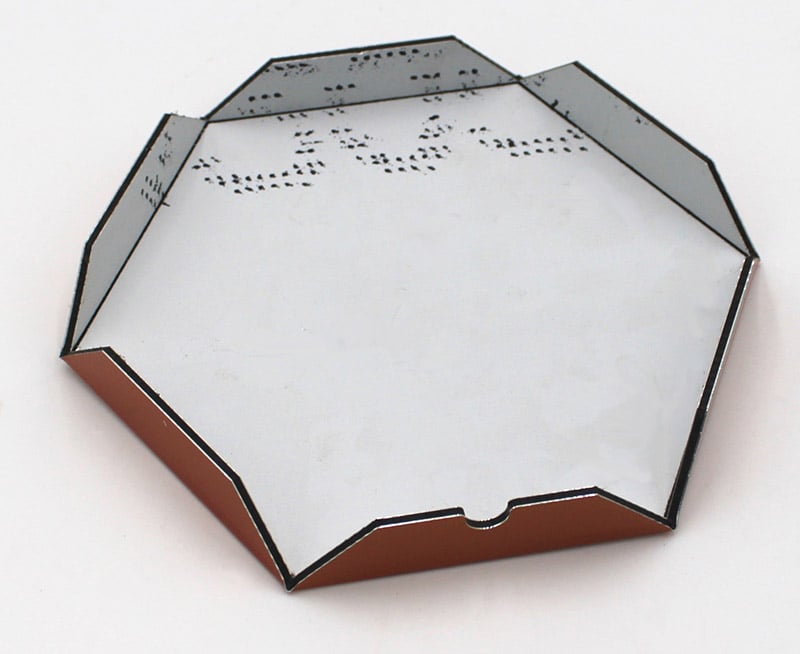

Re-board® / Hexacomb Board

Lightweight, rigid, and 100% recyclable — ideal for flat-pack displays, structures, and furniture.

ACM (Aluminum Composite Material)

Durable, dimensionally stable panels — perfect for signage, wall panels, and precision routing.

Polycarbonate Sheets

Impact-resistant and clear — used for safety shields, machine guards, and enclosures.

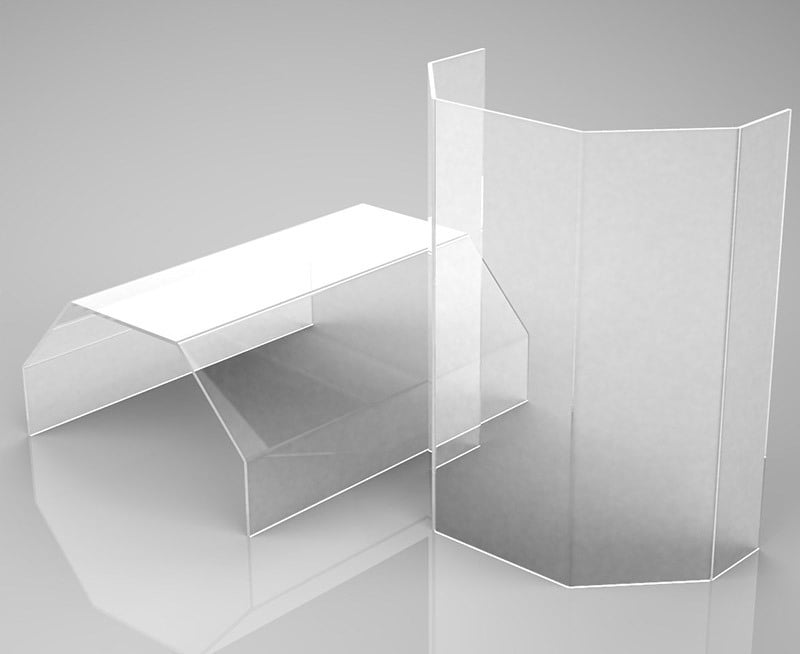

Acrylic (Plexiglass / PMMA)

Glossy, laser-cuttable plastic — great for signage, retail displays, and decorative panels.

Rubber Foam Sheets

Soft, flexible material — perfect for gaskets, padding, packaging inserts, and custom drone packaging

Plywood & Sheet Wood

Versatile material for signage, furniture, and structural panels — CNC cut with precision.

PET Acoustic Material

Sound-absorbing and customizable — ideal for office panels, acoustic baffles, and branded noise control solutions.