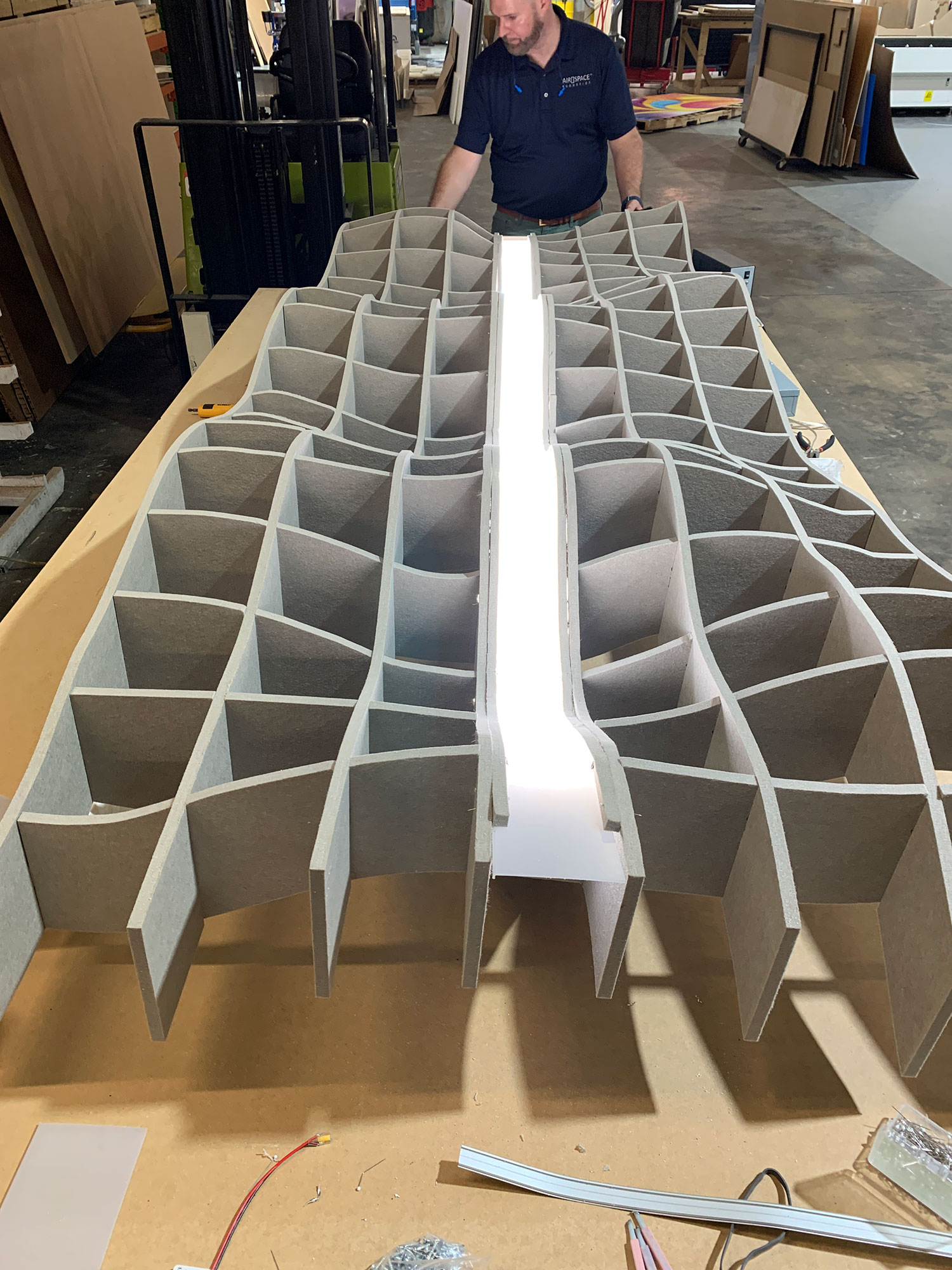

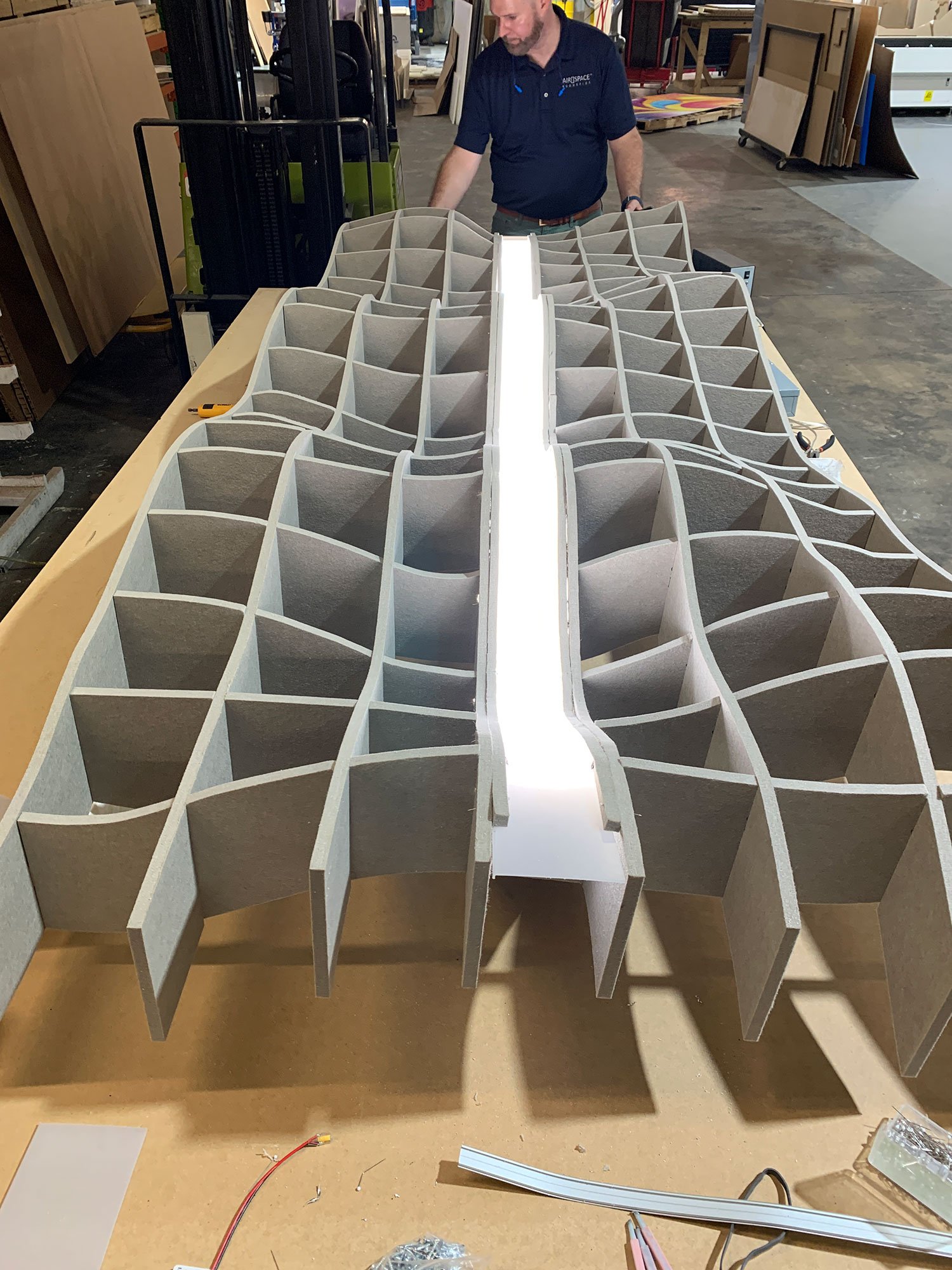

PET Acoustic Panel Cutting Services

Convert PET panels into shaped baffles, branded sound features, and lighting-ready displays.

PET panels into shaped baffles, branded sound features, and lighting-ready displays.

We cut, V-groove, and finish PET acoustic material using our high-precision Kimla Veyron CNC system. Whether you need folded wall features, printed panel kits, or acoustic signage, we can deliver production-ready results.

Advanced Digital Cutting for PET Felt Panels

- Work Area: 84” × 132”

- Max Cutting Thickness: 1.5 inches

- Tooling: Oscillating knife, drag knife, V-cut, creasing wheel

- Camera Registration: For printed PET designs

- Repeatability: ±0.1 mm

- Output: Single units or production runs

- File Support: DXF, SVG, AI

Fabrication Services Offered

- Contour cutting and custom shape profiling

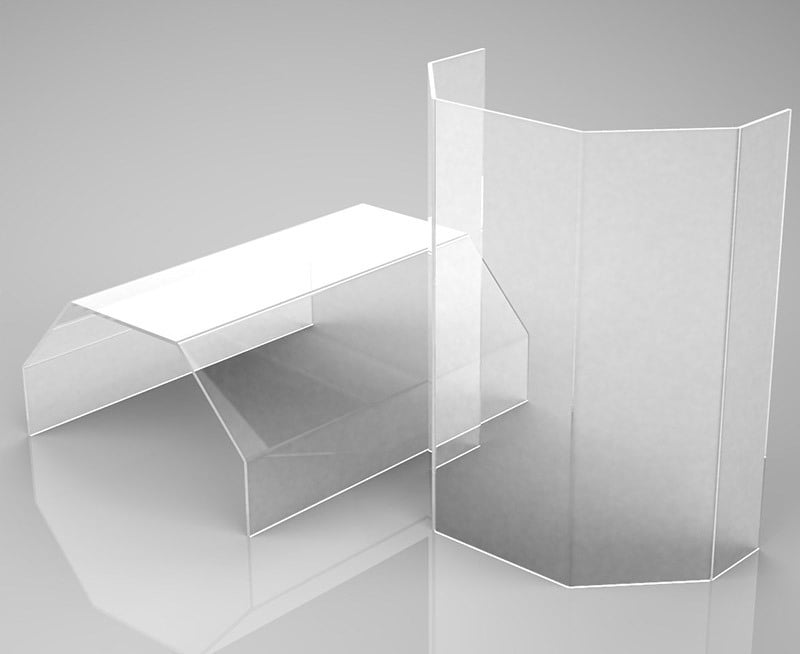

- V-grooving and foldable forms

- Creasing for suspended baffles and partitions

- LED integration for illuminated acoustic elements

- 3D-printed clips and brackets

- Adhesive prep and field assembly kits

Applications for PET Material

-

Wall and ceiling baffles

-

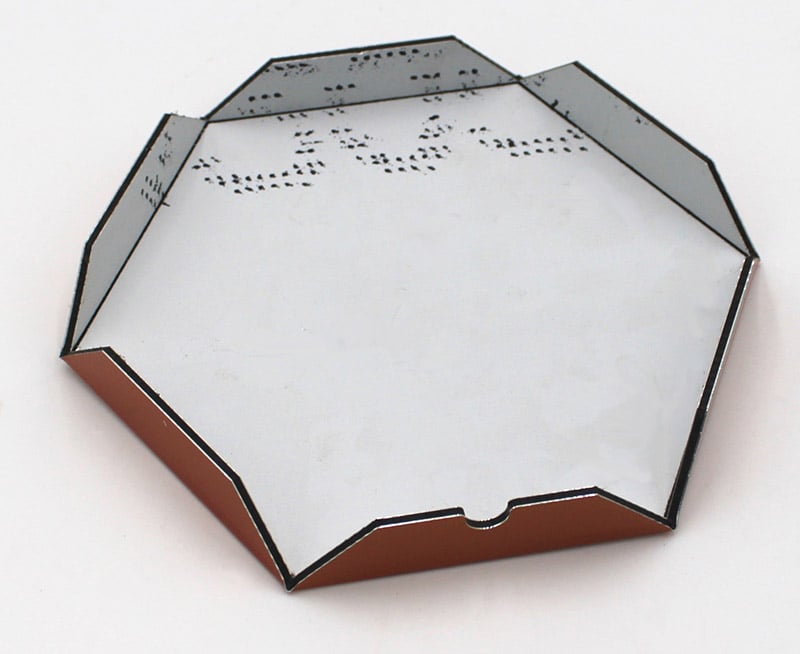

Acoustic signage with logos

-

Retail panels and visual displays

-

Event and booth acoustic dividers

-

Branded acoustic art and lighting

Ideal Use Cases

-

PET acoustic panels

-

Decorative acoustic panels

-

Formable acoustic panels

-

Acoustic room dividers

-

Ceiling acoustic baffles

-

Cut-to-size PET panels

-

Custom acoustic panel cutting

-

Decorative soundproof panels

-

Fabric acoustic panels

-

Felt wall tiles

-

Acoustic ceiling cloud panels

-

Sustainable acoustic solutions

-

Acoustic design elements

-

Quiet interior design

In-store branding and signage

Window displays and visual merchandising

Themed event signage or sculptural props

Photo booth backdrops or 3D logos

High-end dimensional branding for walls and fixtures

Displays for malls, airports, and showrooms

Let’s Fabricate Smarter Sound

We help architects, fabricators, and designers bring acoustic projects to life.

Start an Acoustic Project

Foam Cutting FAQ's

-

Can you create giant foam letters and props?

Yes. We regularly produce giant foam letters, foam logos, and sculptural props for events, retail spaces, and exhibitions. These can be hardcoated, painted, and branded.

-

What is the largest size you can cut?

We can cut up to two foam buns (4' × 4' × 8') at the same time — ideal for both oversized parts and high-output batch runs.

-

What materials are compatible with hot wire cutting?

We cut EPS, XPS, PE, and EPP foams. We do not cut polyurethane, EVA, or spray foam due to health and quality risks.

-

Can your system cut multiple pieces at once?

Yes — our machine supports up to 10 hot wires running in parallel, allowing us to produce multiple identical parts in a single pass.

-

Do you offer foam molds for the concrete industry?

Absolutely. We fabricate custom EPS molds for architectural casting, precast panels, and other concrete forming applications.

-

Do you offer shipping or pick up?

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.

-1.jpg)

Re-board® / Hexacomb Board

Lightweight, rigid, and 100% recyclable — ideal for flat-pack displays, structures, and furniture.

ACM (Aluminum Composite Material)

Durable, dimensionally stable panels — perfect for signage, wall panels, and precision routing.

Polycarbonate Sheets

Impact-resistant and clear — used for safety shields, machine guards, and enclosures.

Acrylic (Plexiglass / PMMA)

Glossy, laser-cuttable plastic — great for signage, retail displays, and decorative panels.

Rubber Foam Sheets

Soft, flexible material — perfect for gaskets, padding, packaging inserts, and custom drone packaging

Plywood & Sheet Wood

Versatile material for signage, furniture, and structural panels — CNC cut with precision.

PET Acoustic Material

Sound-absorbing and customizable — ideal for office panels, acoustic baffles, and branded noise control solutions.