Fabrication & Advanced Product Prototyping

From design files to finished parts — fast, accurate, and built in the USA.

From design files to finished parts — fast, accurate, and built in the USA.

At 865FabLab, we provide end-to-end fabrication services for prototypes, custom parts, retail components, and short-run builds. Whether you’re refining a product idea or need physical parts produced from finalized CAD, we handle cutting, forming, printing, and finishing — all under one roof.

What We Offer

We combine precision fabrication tools with flexible workflows to help you move quickly from idea to physical outcome.

Our prototyping and fabrication services include:

-

CNC routing and contour cutting

-

Laser cutting and engraving

-

Knife cutting and V-grooving for structural boards

-

3D printing for parts, enclosures, and models

-

Vacuum forming for packaging and molded components

-

Material bonding, gluing, assembly, and edge finishing

-

Print-to-cut workflows with camera registration

-

File prep, cleanup, and nesting for efficient production

Equipment We Use

-

Kimla CNC Router — high-accuracy milling of wood, plastics, aluminum

-

Kimla Verone Knife Cutter — perfect for Re-board®, foam, and flexible materials

-

CO₂ Laser Cutter — ideal for acrylic, wood, and detailed cuts

-

Vacuum Former — for forming lightweight plastics over molds

-

FDM & Resin 3D Printers — for fast, strong prototypes

-

Large-format UV printer — for direct-to-substrate graphics

Why Use 865FabLab for Prototyping?

-

Fast lead times — we prioritize short-run and custom jobs

-

B2B focused — we understand deadlines, retail timelines, and pilot phases

-

Material and tooling knowledge built into the process

-

Small quantities welcome — no minimums required

Supported Materials

We fabricate with a wide range of materials, including:

-

Acrylic, polycarbonate, and PETG

-

Re-board®, Swedboard®, Xanita®, Falconboard®

-

Rubber foam, foam board, PVC-free panels

-

Plywood, MDF, and hardwood sheet stock

-

PLA/ABS/Nylon for 3D printed parts

-

Aluminum composite panels (ACM)

Our Process

-

Upload your file or request design support

-

Choose materials or let us recommend based on performance and budget

-

Approve prototype or test cut (optional)

-

We fabricate and finish in-house

-

Pickup or ship nationwide

Ideal for

-

Product developers needing first-run or proof-of-concept builds

-

Industrial designers requiring fast turnaround parts

-

Retail teams building custom displays or packaging

-

Engineers validating mechanical fit and function

-

Startups launching limited runs before scaling

In-store branding and signage

Window displays and visual merchandising

Themed event signage or sculptural props

Photo booth backdrops or 3D logos

High-end dimensional branding for walls and fixtures

Displays for malls, airports, and showrooms

Ready to Fabricate or Prototype Something?

We’re here to help you move from concept to reality — with tools that match your ambition and speed.

Start a Prototype Project

Product Prototyping FAQ's

-

Can you help with both the prototype and final product?

Yes — we can build an initial prototype and scale up to short-run production if needed.

-

How fast can you produce a prototype?

Turnaround ranges from 1–5 business days depending on complexity and material availability.

-

Can I use my own material?

Yes — we can cut or form customer-supplied material, depending on type and condition.

-

Do you offer post-processing like sanding or assembly?

Yes — we offer light finishing, assembly, and gluing options depending on the project.

-

Do you offer shipping or pickup?

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.

-1.jpg)

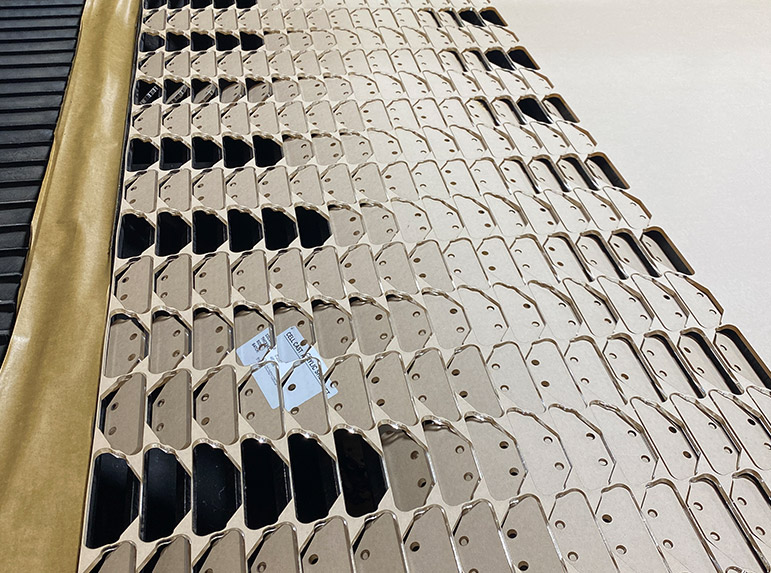

Re-board® / Hexacomb Board

Lightweight, rigid, and 100% recyclable — ideal for flat-pack displays, structures, and furniture.

ACM (Aluminum Composite Material)

Durable, dimensionally stable panels — perfect for signage, wall panels, and precision routing.

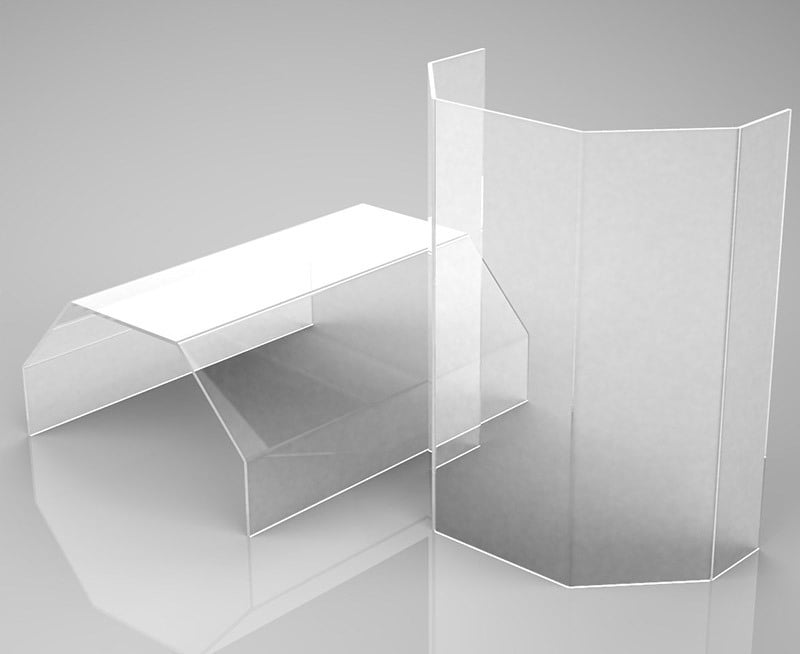

Polycarbonate Sheets

Impact-resistant and clear — used for safety shields, machine guards, and enclosures.

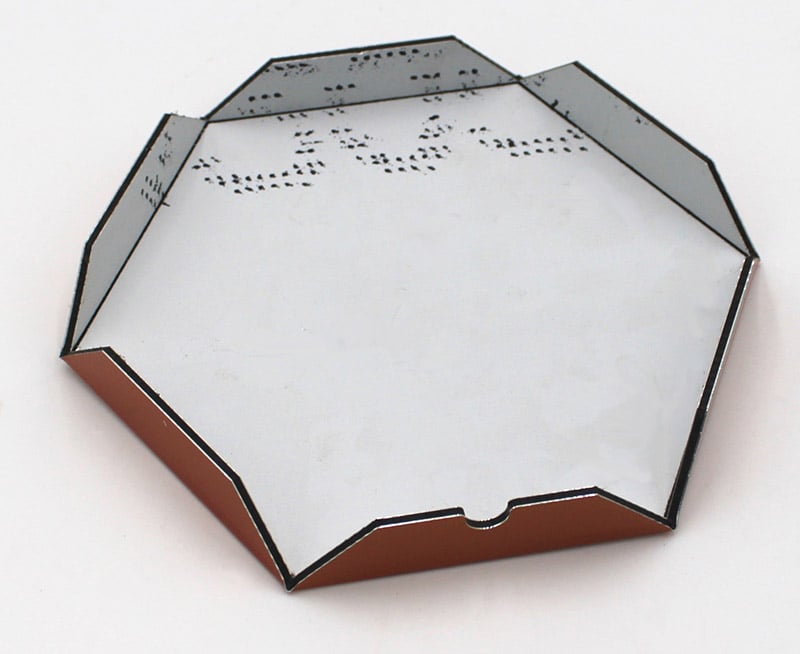

Acrylic (Plexiglass / PMMA)

Glossy, laser-cuttable plastic — great for signage, retail displays, and decorative panels.

Rubber Foam Sheets

Soft, flexible material — perfect for gaskets, padding, packaging inserts, and custom drone packaging

Plywood & Sheet Wood

Versatile material for signage, furniture, and structural panels — CNC cut with precision.

PET Acoustic Material

Sound-absorbing and customizable — ideal for office panels, acoustic baffles, and branded noise control solutions.