Vacuum Forming / Thermoforming Services

Turn flat plastic sheets into custom 3D shapes — fast, accurate, and scalable.

Turn flat plastic sheets into custom 3D shapes — fast, accurate, and scalable.

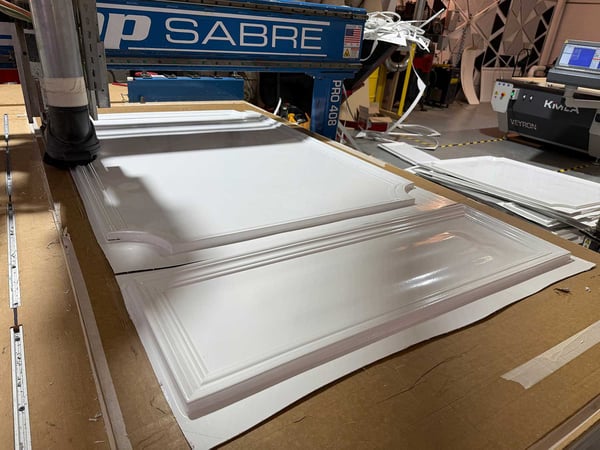

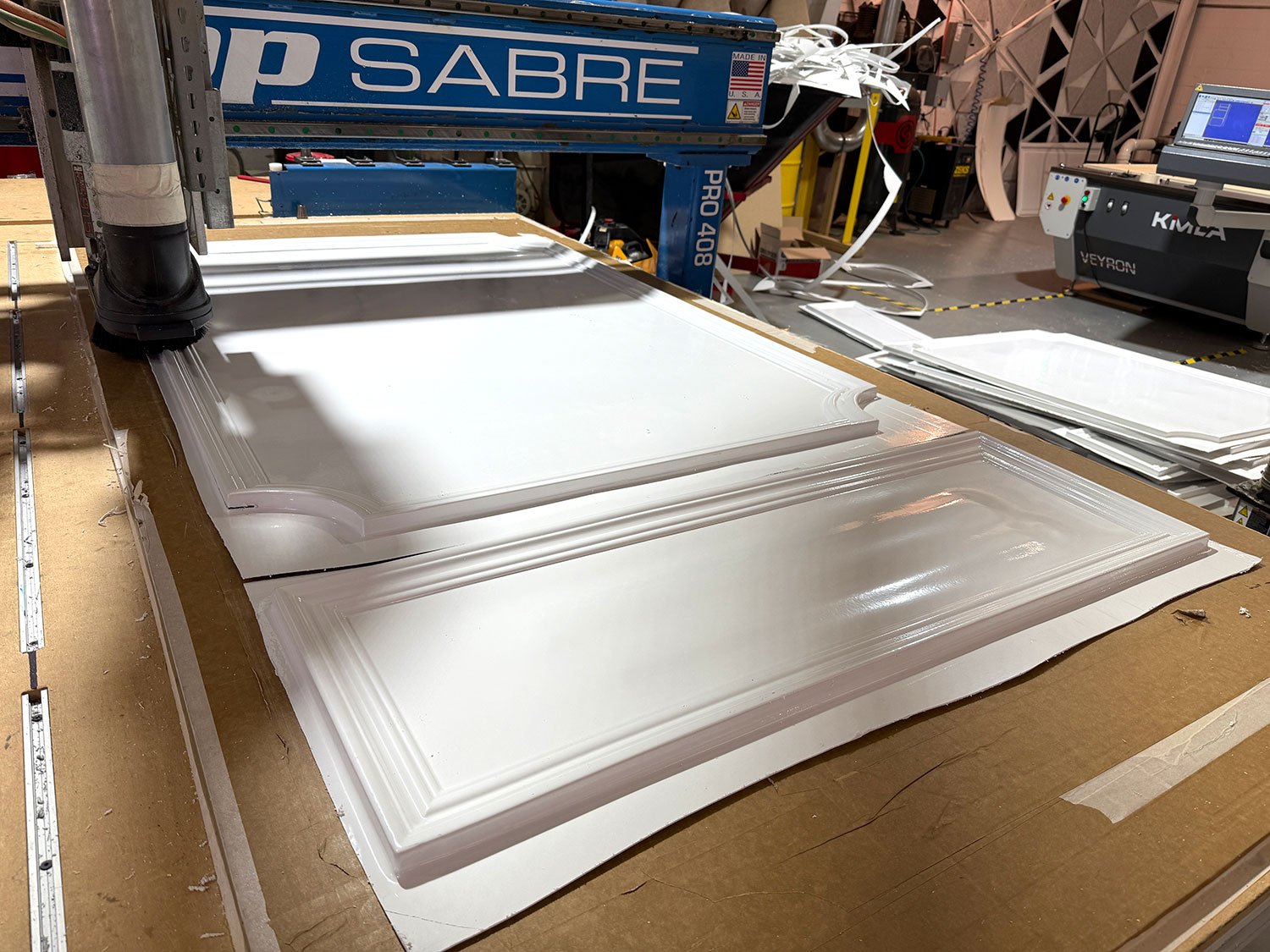

At 865FabLab, our vacuum forming service enables you to take plastic sheets and transform them into contoured parts, covers, trays, enclosures, signage elements, and more. We combine material knowledge, tooling, and thermal forming expertise to deliver reliable results for prototypes and production runs.

What We Offer

-

Sheet-fed vacuum forming of thermoplastics (ABS, acrylic, PETG, PVC, etc.)

-

Deep draws and moderate contours (up to ~22 inches in depth)

-

Pneumatic clamping and adjustable frames for clean edges

-

Precision heating control (infrared radiant panels, percentage heat control)

-

High-vacuum performance with surge tank for stable forming

-

Tooling support: plug assists, draft angles, venting

-

Finishing, trimming, flange trimming, and secondary processing

Typical Specs & Capabilities

-

Max sheet size: 48″ × 96″ (122 × 244 cm)

-

Depth of draw (max): up to about 22 inches (55 cm)

-

Material gauges supported: up to ¼ inch (0.64 cm)

-

Clamping frame: fully adjustable, pneumatic drive (~300 lb seal pressure) (belovac.com)

-

Heating system: Infrared radiant heater with “percentage control” (0–100%) and “size-down” capability

-

Vacuum / pump system: High-volume vacuum with onboard surge tank (often 40+ gallon)

-

Control & automation options: Programmable heating timers, optional PLC control, multi-zone heating capability

Materials We Commonly Form

We support a variety of thermoplastics and sheet materials, including:

-

ABS, HIPS, acrylic, PETG, PVC

-

Kydex and other specialty plastics

-

Sheets up to ¼" thick (depending on material)

-

Pretreated sheets (if needed) for deep draw or thicker parts

Process Overview

-

Submit your design or 3D model, or ask us to assist with tool design

-

Choose material & thickness based on part needs

-

We build or source tooling (mold, plug assist, decking)

-

Sheet heating, stretching, and vacuum forming

-

Trim and finish to final geometry

-

Pickup or ship — including protection and packaging

Ideal Applications

-

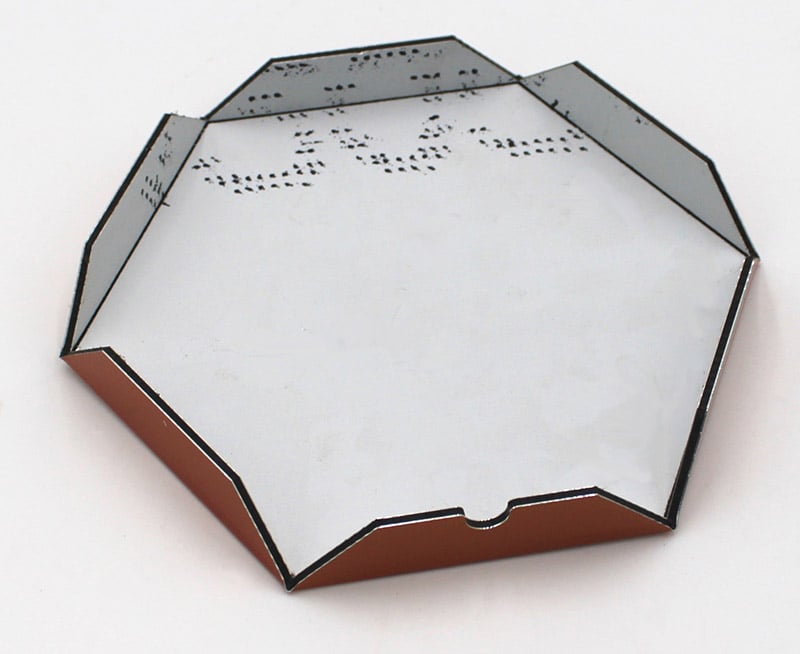

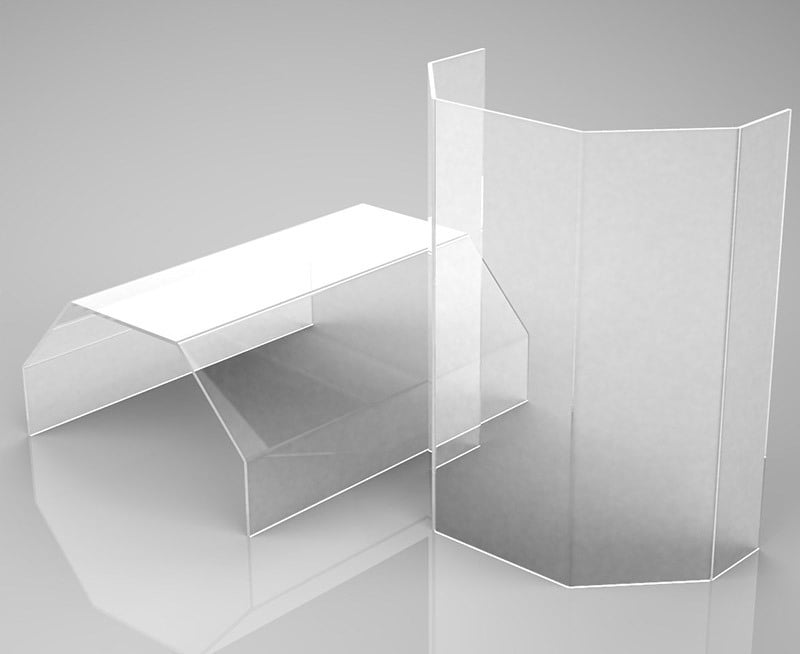

Enclosures, housings, and covers

-

Trays, inserts, bins, and packaging

-

POP/retail display shells

-

Clamshells, blister dials, faceplates

-

Architectural decorative elements

-

Prototyping complex plastic forms

In-store branding and signage

Window displays and visual merchandising

Themed event signage or sculptural props

Photo booth backdrops or 3D logos

High-end dimensional branding for walls and fixtures

Displays for malls, airports, and showrooms

.jpeg)

.jpeg?width=500&height=500&name=File%20Oct%2008%202025%2c%208%2059%2025%20PM%20(2).jpeg)

Get Started with Vacuum Forming

Whether you have a concrete idea or just a vision, we can help you turn flat plastic into 3D form.

Start a Vacuum Forming Project

Vacuum Forming FAQ's

-

Can you form deep cavities?

Yes — we can form parts with depths up to ~22 inches depending on material and tooling.

-

What thickness of plastic can you form?

We accommodate materials up to about ¼ inch thickness, depending on the plastic type, tooling, and part geometry.

-

Do you provide the tooling (molds/plugs)?

Yes — we can either work with customer-supplied molds or create tooling in-house depending on the project.

-

What is the lead time for vacuum forming jobs?

Lead times depend on part complexity, tooling needs, and volume — often between a few days to a week for prototyping runs.

-

Do you offer shipping or pickup?

We offer both. Orders can be picked up at our Powell, TN facility or shipped anywhere in the USA.

-1.jpg)

Re-board® / Hexacomb Board

Lightweight, rigid, and 100% recyclable — ideal for flat-pack displays, structures, and furniture.

ACM (Aluminum Composite Material)

Durable, dimensionally stable panels — perfect for signage, wall panels, and precision routing.

Polycarbonate Sheets

Impact-resistant and clear — used for safety shields, machine guards, and enclosures.

Acrylic (Plexiglass / PMMA)

Glossy, laser-cuttable plastic — great for signage, retail displays, and decorative panels.

Rubber Foam Sheets

Soft, flexible material — perfect for gaskets, padding, packaging inserts, and custom drone packaging

Plywood & Sheet Wood

Versatile material for signage, furniture, and structural panels — CNC cut with precision.

PET Acoustic Material

Sound-absorbing and customizable — ideal for office panels, acoustic baffles, and branded noise control solutions.